2026 How to Choose the Right Electric Lift Actuator for Your Needs?

Choosing the right Electric Lift Actuator can be a daunting task. As industry expert Dr. Emily Hart states, “Selecting an actuator should meet specific performance needs.” Her insight highlights the importance of understanding individual requirements.

Many factors impact this decision. These include load capacity, stroke length, and power supply options. Each application is unique, and what works for one may not suit another. It's crucial to consider the environment too. Harsh conditions may require a more robust design.

Flexibility in options exists, yet it can complicate choices. Some users may underestimate their needs. Others might overlook essential features. A thoughtful approach is necessary to avoid costly mistakes. In this journey, guidance is invaluable to ensure the right fit for an Electric Lift Actuator.

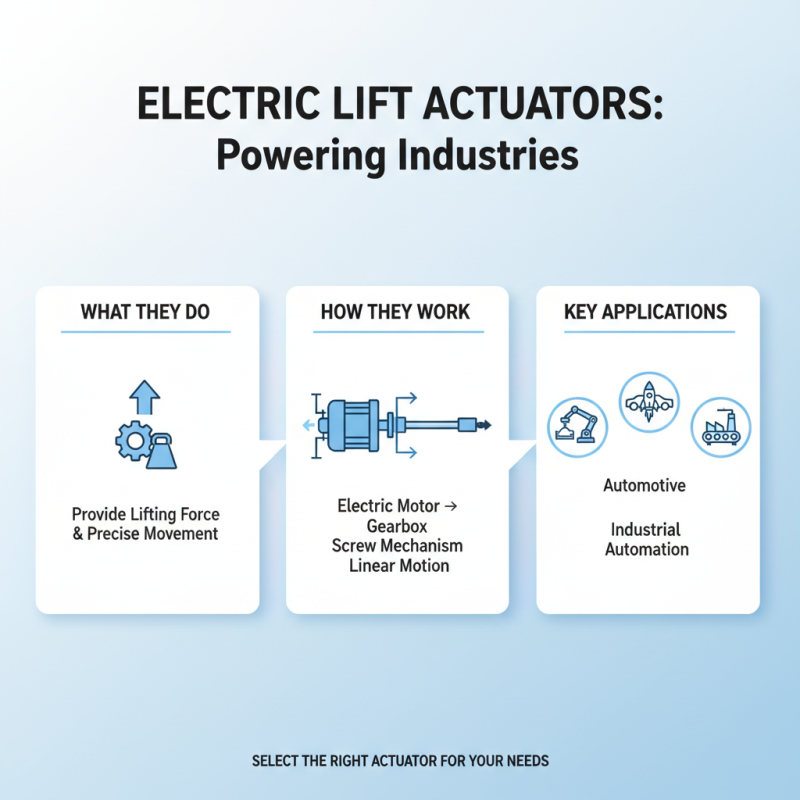

Understanding the Basics of Electric Lift Actuators

Electric lift actuators play a crucial role in various industries. They provide the necessary lifting force for applications such as automotive, aerospace, and industrial automation. Understanding how they work can help in selecting the right actuator for your needs.

These actuators convert electrical energy into mechanical motion, allowing for precise control. The global market for electric actuators was valued at approximately $4.5 billion in 2022 and is expected to grow. Reports suggest a compound annual growth rate (CAGR) of around 6.2% through 2028. This growth implies a rising demand for more efficient and versatile electric lift actuators.

When choosing an electric lift actuator, consider factors such as load capacity, speed, and stroke length. For instance, many applications require actuators that can handle loads between 200 to 1000 pounds. Additionally, typical stroke lengths vary from 6 to 36 inches, depending on the specific use. Reflecting on these aspects can simplify decision-making. However, complexities remain, like ensuring compatibility with existing systems. This reflection is essential to avoid costly mistakes.

Key Factors to Consider When Selecting an Electric Lift Actuator

When choosing an electric lift actuator, several key factors come into play. The load capacity is crucial. You must ensure the actuator can handle the weight it will bear. Consider the vertical travel distance needed for your application. This measurement determines how far the actuator must move. Additionally, speed is important. Some tasks require quick movements, while others benefit from slow, deliberate action.

Another factor to ponder is the environment where the actuator will operate. Will it be exposed to moisture or dust? Certain actuators are better suited for harsh conditions. Think about the duty cycle, too. How often will it operate? Continuous use might lead to wear and tear, necessitating a more robust model.

Don't forget to assess control options. Different systems may require specific control methods. Compatibility with existing setups should also be reviewed. While these considerations feel overwhelming, take your time to evaluate your unique needs. Reflect on your previous choices; it may lead to better decisions now.

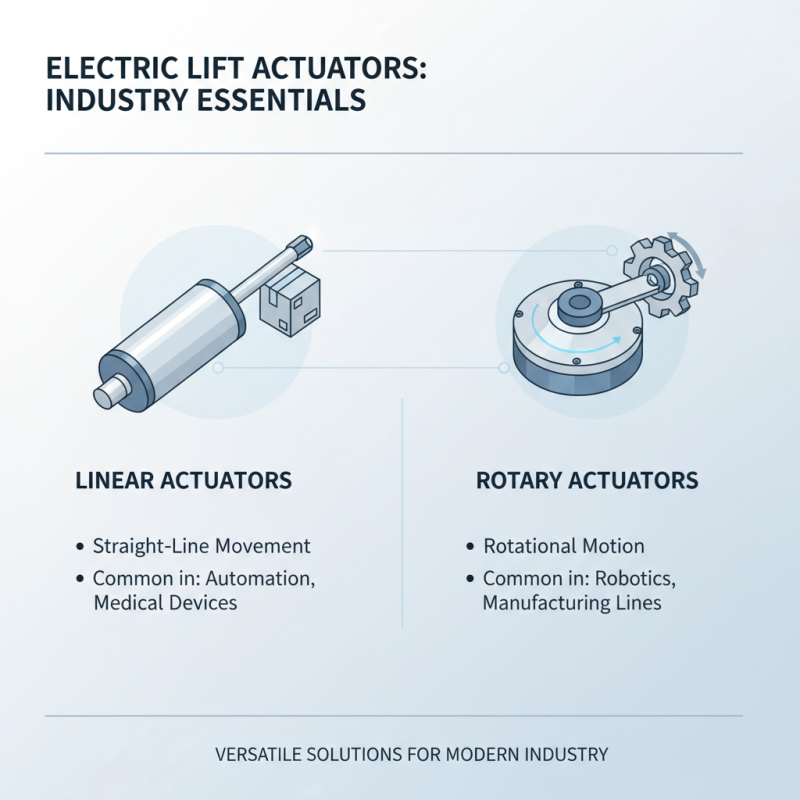

Different Types of Electric Lift Actuators and Their Applications

Electric lift actuators are crucial in various industries. They come in different types, each serving unique purposes. Linear actuators are popular in applications requiring straight-line movement. For instance, they excel in automation settings and medical devices. Rotary actuators, on the other hand, provide rotational motion. They are used in robotics and manufacturing lines.

When selecting an actuator, it's vital to consider the load capacity. Industry reports indicate that over 50% of failures are due to underestimating this. Look for products that balance power and efficiency. Electric actuators have improved energy use, achieving up to 90% efficiency. However, some designs can still draw excess energy.

In addition to load, speed is a critical factor. The average speed range for electric lift actuators is between 5 mm/s to 100 mm/s. Applications often require specific speed settings. Choosing a versatile model can be challenging. Potential buyers must weigh their options carefully. Performance expectations should align with application needs.

How Load Capacity Influences Your Choice of Electric Lift Actuator

When selecting an electric lift actuator, load capacity plays a crucial role. The actuator's load capacity determines how much weight it can handle safely. If the actuator is underloaded, it may not operate efficiently. Conversely, exceeding its capacity can lead to mechanical failure. Consider the specific application and the weight involved.

Evaluate the maximum load you expect the actuator to lift. It's essential to account for not just the weight of the object. Additional factors may include dynamic loads and potential impacts during operation. Users often underestimate these elements, leading to poor performance.

Be cautious about vague specifications. Always check the details and ensure they meet your needs. It is often tempting to choose a more powerful actuator, but this may not be necessary. A well-sized actuator avoids unnecessary energy consumption and potential wear. Reflect on your requirements carefully before making a final decision.

Essential Features to Look for in an Electric Lift Actuator

When choosing the right electric lift actuator, several essential features must be considered. Load capacity is critical. According to industry reports, a significant number of failures arise from exceeding the actuator's weight limit. Always ensure that the actuator can handle both static and dynamic loads. An actuator rated for at least 10% more than the expected load is a reasonable guideline.

Speed and stroke length also play vital roles in selection. An ideal actuator should operate at an efficient speed, balancing power and responsiveness. For example, actuators with speeds between 30 and 50 mm per second often meet industrial needs. Additionally, stroke length varies widely. Actuators should provide a range that accommodates your project’s specific movement requirements. Some applications might require long strokes for larger machinery.

Another key factor is energy efficiency. Increasingly, manufacturers are focusing on actuators that minimize energy consumption. Reports indicate that efficient actuators can reduce energy usage by up to 25%. This not only cuts costs but reduces environmental impact. However, it's crucial to assess the initial investment versus long-term savings. Some actuators may have a higher upfront cost but lead to significant savings over time. Be mindful that this decision requires careful consideration of operational demands.

Home

About Us

Products

Window Lifter

Window Lifter

Grille

RB

Vehicle Model

ALFA ROMEO

AUDI

BMW

BOMBARDIER

BUICK

BYD

CADILLAC

CHEVROLET

CHRYSLER

CITROEN

DACIA

DODGE

DS

FIAT

FORD

GMC

HYUNDAI

INFINITI

JAGUAR

JEEP

KENWORTH

KIA

LAND ROVER

LINCOLN

LVECO

MAZDA

MERCEDES BENZ

MINI

NISSAN

OPEL

PETERBILT

PEUGEOT

POLARIS

PONTIAC

PORSCHE

RENAULT

RENAULT SAMSUNG MOTO

SEAT

SKODA

SUBARU

SUZUKI

TESLA

TOYOTA

VOLKSWAGEN

VOLVO

News

FAQ

Blog

Contact Us